Step 4: The correct filling height can be checked with the engraved ruler on the capillary filling tool. The 'bouncing effect' causes tight packing of the substance and avoids the inclusion of air pockets. This action packs the sample tightly down into the bottom of the capillary. Step 3: The small amount of sample at the top of the capillaries is then moved down the capillary by releasing the grip and gently bouncing the capillaries on the table several times. Collecting a small sample portion from a mortar is easily done with the assistance of the tool. The capillary filling tool perfectly assists the filling as the empty capillaries are securely held in a peg-like grip. Step 2: Several capillaries are prepared simultaneously for measurement with a METTLER TOLEDO instrument. Then a small portion of sample is finely ground in a mortar. Step 1: First, the sample needs to be dried in a desiccator. Sample preparation process using METTLER TOLEDO melting point tools: Compared to other physical values the change in light transmission can easily be determined and can therefore be used for melting point detection. Last but not least, the optical properties birefringence reflection and light transmission change. Amongst these are the thermodynamic values, specific heat capacity, enthalpy, and rheological properties such as volume or viscosity. The melting temperature of a crystalline solid is thus an indicator for the stability of its lattice.Īt the melting point not only the aggregate state changes quite a lot of other physical characteristics also change significantly. The more energy is needed, the higher the melting point.

The stronger the forces of attraction between the particles, the more energy is needed to overcome them. The crystalline structure is destroyed and the solid material melts.

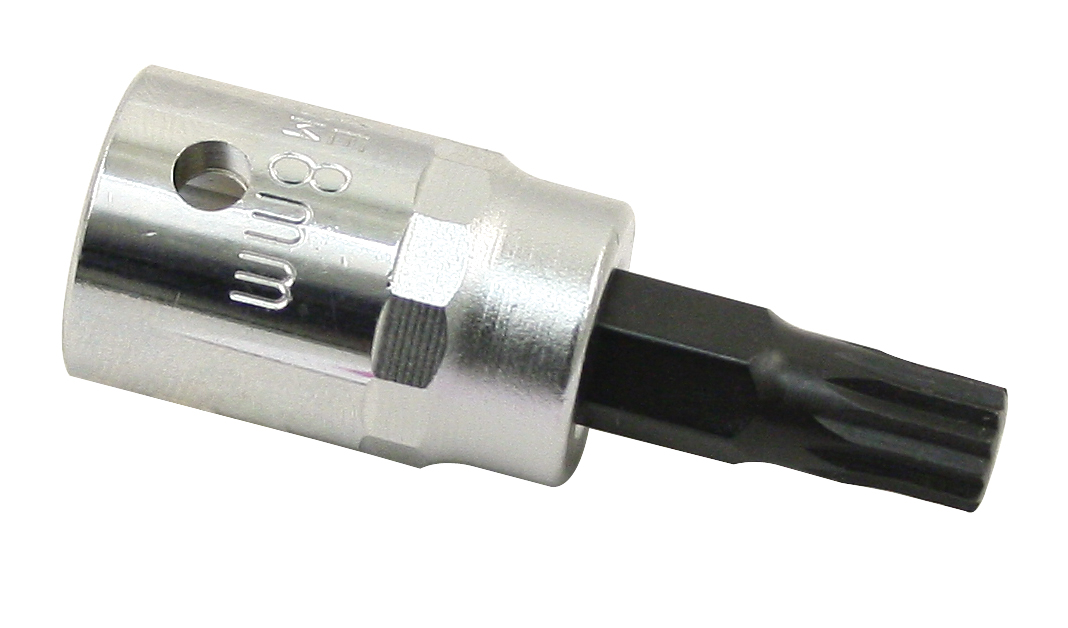

When the solid crystalline material is heated, the particles become more energetic and start to move more strongly, until finally the forces of attraction between them are no longer strong enough to hold them together. The particles within the lattice are held together by lattice forces. During the phase transition, the two physical phases of the material exist side-by-side.Ĭrystalline materials consist of fine particles that for a regular, 3-dimensional arrangement – a crystalline lattice. During the melting process, all of the energy added to the substance is consumed as heat of fusion, and the temperature remains constant (see diagram below). This phenomenon occurs when the substance is heated. It is the temperature at which the solid phase changes to the liquid phase. Sold individually or as part of a set, you're guaranteed to find the setup you need.Melting point is a characteristic property of solid crystalline substance. This helps to prevent damage to nuts and bolts and makes it possible to also grip nuts and bolts which have damaged corners. "Hip grip" ensures that the socket will grip on the flat surfaces of the nut rather than on the corners. Whichever style you decide to choose all of our sockets have been manufactured according to our signature "hip grip" system. 12 point sockets are also great for use in tight spaces as they allow you to connect to a fastener at more angles.This is ideal if you are trying to work on a fastener that is hard to see or you cannot see at all.

The additional points make these sockets easier to connect with the heads of fasteners.The thicker walls also add a lot of overall strength.Slipping strips bolts and that's definitely something you don't want to do.Additional contact surface along the flat edges of the socket make it less likely to slip.Ideal for jobs that require a large amount of force.The answer? Well it depends on the job you're looking to do. Which should you use, 6 point sockets or 12 point sockets? It's a question we get asked all the time.

0 kommentar(er)

0 kommentar(er)